With the new revision of the EU Waste Framework Directive, we are entering a phase where textile waste management is no longer optional, but a structural pillar: mandatory separate collection, extended producer responsibility, waste hierarchy prioritisation, export controls, and a clear framework for sustainable design.

But beyond the regulatory framework, what this triggers is something else: a wave of forced innovation across every stage of the textile lifecycle — from design and production to use and end-of-life.

And, as always, hardware lags behind the targets. Scaling up reuse and recycling — the most sustainable options for end-of-life garments — will not be possible unless we can process more volume, at better quality, and at reasonable cost.

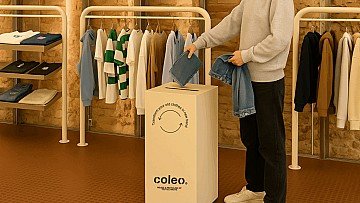

Garment collection

We need containers specifically designed for textiles, equipped with systems that minimise contamination from non-textile waste and are resistant to vandalism.

At the same time, logistics must be efficient, ensuring that transport costs have as little economic and environmental impact as possible.

Sorting

The process of sorting garments by composition and colour has made major advances thanks to near-infrared (NIR) technology and artificial intelligence. But there is still a long way to go in defining and standardising composition and colour codes that allow for homogeneous material streams.

We need a shared taxonomy that considers fibre type, purity, waste format (garment, offcut, fibre…), colour tone and degradation level.

And then there’s a less trendy but fundamental challenge: garment-by-garment feeding. Today, it still relies heavily on manual labour, and automation remains expensive. A wide-open field for industrial innovation.

Preparation for recycling

Removing zippers, buttons, labels. Preprocessing efficiently. Extracting maximum value from waste as a resource, and ensuring the defibration process yields increasingly high-quality fibres — once again, competitively and at scale — is not just a challenge to solve, but one to continuously improve on.

Investing in hardware means investing in the system

Innovation in this sector is not just about building machines.

It’s about understanding the full model — connecting political vision, regulatory pressure, business commitment and ecological urgency.

Because what’s at stake isn’t just compliance, but the real ability to transform waste into resources at industrial scale.

And for that, we need investment, we need time — but above all, we need resolve.

Because looking at the ecological imbalance we’ve reached — and in which textiles play a part — the challenge isn’t just technical.

It’s political, economic and cultural.

We keep going, with an optimistic view of what’s ahead.