The global transition to sustainable energy faces a critical hurdle in the adoption of green hydrogen. Despite its potential as a clean and versatile energy carrier, green hydrogen remains limited in its adoption due to two significant challenges: high production costs and complex distribution logistics. WtEnergy Advanced Solutions is addressing these barriers head-on through its innovative approaches to hydrogen production and delivery.

The Cost Barrier: Why Green Hydrogen is Expensive

One of the major factors impeding the widespread adoption of green hydrogen is its cost. Currently, approximately 50% of green hydrogen production expenses stem from electrolysis, the process of splitting water into hydrogen and oxygen using electricity from renewable sources. This method, while clean, is energy-intensive and costly. In comparison, hydrogen derived from fossil fuels, often referred to as gray hydrogen, is significantly cheaper but carries a heavy environmental cost.

WtEnergy’s approach offers a transformative alternative by utilizing advanced gasification technology to produce hydrogen from biomass and organic waste. This method not only reduces dependency on costly electrolysis but also leverages locally available resources, cutting production costs substantially. By generating hydrogen at nearly half the cost of conventional methods, WtEnergy makes green hydrogen a more viable option for industries and consumers alike.

Distribution Challenges: The Cost of Moving Hydrogen

Hydrogen’s low density makes its storage and transportation a complex and expensive endeavor. Current distribution methods often involve compressing or liquefying hydrogen, which requires additional energy and infrastructure investments. These logistical challenges significantly inflate the cost of delivering hydrogen to end users.

WtEnergy addresses this issue by producing hydrogen close to the point of consumption. By decentralizing production and situating facilities near industrial hubs or areas of high demand, WtEnergy minimizes transportation costs and logistical complexities. This localized production model not only enhances accessibility but also reduces the environmental impact associated with hydrogen transport.

HYIELD Project: From Bio-Waste to Green Hydrogen

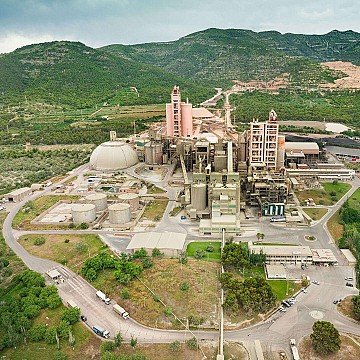

WtEnergy’s HYIELD project exemplifies the transformative potential of its technologies. Located at Cemex’s Alcanar cement facility in Spain, this demonstration plant uses advanced steam gasification and Syngas purification to convert bio-waste into green hydrogen. The plant achieves an impressive 64% energy conversion efficiency and produces hydrogen with a purity of 99.97%, suitable for diverse industrial applications.

Over the 15-month testing period, the facility will process approximately 2,272 tons of dry biomass annually, yielding around 380 tons of green hydrogen.

Syngas: A Complementary Solution

Beyond hydrogen, WtEnergy’s Syngas technology further supports industrial decarbonization. Syngas, a mixture of hydrogen, carbon monoxide, and other gases, can be produced from the same biomass and organic waste sources. It provides an immediate, cost-effective alternative to fossil fuels for industries, enabling a smoother transition towards cleaner energy systems.

Economic and Environmental Benefits

The HYIELD project reduces reliance on fossil fuels and incorporates circular economy principles by converting waste into valuable resources. Its hydrogen production cost is less than 50% of the cost associated with traditional electrolysis methods. Additionally, the process captures approximately 1,810 kg of CO2 per ton of biomass processed, preventing nearly 4,200 tons of CO2 emissions annually based on 4,000 operational hours.

Driving a Sustainable Transition

WtEnergy’s innovative technologies are reshaping the landscape of green hydrogen and sustainable energy. By tackling the dual challenges of cost and distribution, the company is driving the adoption of green hydrogen and fostering a circular economy. These advancements not only lower emissions but also create a robust framework for a cleaner and more resilient industrial future.

As the world intensifies its efforts to combat climate change, solutions like those pioneered by WtEnergy are crucial. By making green hydrogen more accessible and affordable, the company is playing a crucial role in unlocking its full potential as a foundation for the global energy transition.