An article published in Cemnet.com in November 2025.

In Spain the first waste-to-energy gasifier in the cement industry will be commissioned at the end of 2025. The milestone installation is expected to support the wider use of alternative fuels in cement kilns thanks to gasification of biomass and waste-derived fuels into a clean and homogenous Syngas, ready for use in kiln firing.

The cement industry is under mounting pressure to decarbonise while ensuring cost competitiveness and operational reliability. Alternative fuels (AFs) such as refuse-derived fuel (RDF) and solid recovered fuel (SRF) are widely available and affordable, but their use is often limited by impurities, variability and operational risks. In particular, flame characteristics and thermal performance are often insufficient to ensure the specific process conditions required to produce clinker. At the same time, chlorine content has long posed a barrier, causing kiln instability, build-ups and blockages in cyclones, precalciner and ducts as well as equipment corrosion, environmental noncompliance and a decline in clinker quality.

To address these challenges, WtEnergy Advanced Solutions developed SynTK (Syngas-to-Kiln), a technology that gasifies biomass and waste-derived solid fuels into clean, homogenous Syngas for direct use in thermal process applications. This innovative CleanTech solution enables cement producers to substitute fossil fuels with confidence, while improving flame stability, enhancing combustion reactions and ensuringconsistent thermal performance in the main burner. By optimising these combustion characteristics, SynTK not only maintains clinker quality but also provides operational flexibility and long-term process efficiency.

Additionally, SynTK is suitable even for white cement production, where it does not affect the final colour, and it reduces reliance on costly carbon capture, utilisation and storage (CCUS) solutions, which often require government subsidies due to high implementation costs.

The project

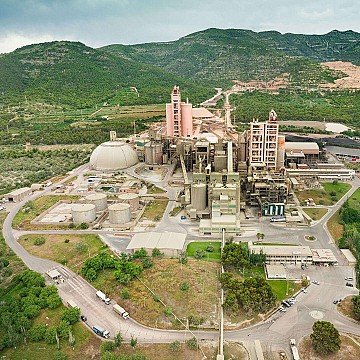

The world’s first waste-to-energy gasifier for the cement industry represents a global milestone, the first industrial scale application of gasification technology in cement production.

The SynTK system is integrated as a parallel fuel supply to the clinker kiln and precalciner. It primarily uses RDF but also accommodates other alternative feedstocks, such as SRF, dried sewage sludge, meat and bone meal, used tyres and biomass, providing significant fuel flexibility. The system converts these feedstocks into a clean Syngas, a combustible gas primarily composed of CO, H₂, and CH₄, that can be used directly in the combustion process, replacing fossil fuels such as petcoke or coal. This achievement not only validates the technology but also demonstrates its viability in one of the most demanding industrial sectors.

Key challenges

One of the major challenges was convincing a leading international cement producer to adopt a first-of-its-kind technology. Implementing SynTK required overcoming concerns about reliability and potential risks in such a critical process. However, the system delivers consistent heat transfer and combustion performance comparable to petcoke to ensure seamless integration into kiln operations.

An additional challenge was chlorine. The RDF available for this project contained high chlorine levels, which would normally prevent its use in cement kilns due to the risk of equipment corrosion, environmental issues and negative effects on clinker quality.

Syngas solution

WtEnergy Advanced Solutions addressed these concerns by tailoring the SynTK system to meet the specific needs of the project. Through advanced gasification and proprietary cleaning stages, chlorine levels in the fuel stream were reduced by over 90 per cent.

This breakthrough enabled the safe use of RDF with high chlorine content, unlocking access to significantly cheaper and more abundant fuels. The Syngas produced offers stable flame characteristics and equivalent thermal performance to petcoke in the kiln’s first 15m.

Moreover, the system was fully automated and integrated with the plant’s distributed control system (DCS), ensuring continuous monitoring, safe operation and stable process conditions. In addition to addressing operational challenges, SynTK represents a highly cost effective solution.

Results

The project delivers impressive environmental and economic outcomes. The SynTK system enables 30MW of fuel substitution, with an overall efficiency of 94-97 per cent.

In addition, emission levels declined 99 per cent for particulates and 90 per cent for chlorine, while chlorine-containing ash was reduced to less than 1000tpa. In addition, the system achieves 95 per cent alkali removal and 50 per cent sulphur reduction.

In terms of environmental performance, the project achieves a reduction of 55,000tpa of CO₂ emissions. This translates into significant annual fuel cost savings, with a payback period of just two years.

These data represent a step change in fuel quality, enabling cement producers to safely utilise low-cost fuel streams that were previously considered too risky or low grade.

The result is a cleaner, more predictable flame, improved heat transfer and reduced equipment wear.

Application in white cement production

The project also provides key insights for the white cement

sector, which has traditionally faced strict limitations on fuel substitution. Producers must use very specific fuels to avoid altering the final product’s colour, leading to extremely low substitution rates and higher energy costs. SynTK overcomes these limitations.

The combustion of clean Syngas does not affect cement whiteness, allowing producers to maintain product quality while significantly increasing substitution rates.

By enabling the use of low-cost, high chlorine fuels, SynTK reduces energy costs and broadens fuel supply options without relying entirely on expensive CCUS solutions, which require government financial support to be economically viable.

A scalable pathway for the sector

This project demonstrates that SynTK is a game-changer for the cement industry.

By addressing both the long standing challenge of chlorine in alternative fuels as well as optimising flame and thermal performance, it unlocks the use of low–cost, high-availability feedstocks, while delivering measurable environmental and economic benefits. This technology offers a scalable, modular and low-risk path to meeting these goals.

The world’s first waste-to-energy gasifier for the cement industry in Spain marks a turning point in the sector’s energy transition. With its scalability, efficiency and proven return on investment, SynTK offers cement producers a reliable pathway to decarbonisation, fuel security and circular economy leadership.